The development of modern industry has placed increasing demands on the environment of experimentation, research and production. The main way to achieve this requirement is to widely use air filters in clean air conditioning systems. Among them, HEPA and ULPA filters are the last protection for dust particles entering the clean room. Its performance is directly related to the clean room level, which in turn affects the process and product quality. Therefore, it is meaningful to conduct experimental research on the filter. The resistance performance and filtration performance of the two filters were compared at different wind speeds by measuring the filtration efficiency of the glass fiber filter and the PTFE filter for 0.3 μm, 0.5 μm, 1.0 μm P.A.O particles. The results show that wind speed is a very important factor affecting the filtration efficiency of HEPA air filters. The higher the wind speed, the lower the filtration efficiency, and the effect is more obvious for PTFE filters.

Key words: HEPA air filter;Resistance performance; filtration performance; PTFE filter paper; glass fiber filter paper; glass fiber filter.

CLC number:X964 Document identification code: A

With the continuous development of science and technology, the production and modernization of modern industrial products have become more and more demanding for indoor air cleanliness. In particular, microelectronics, medical, chemical, biological, food processing and other industries require miniaturization. Precision, high purity, high quality and high reliability indoor environment, which puts higher and higher requirements on the performance of HEPA air filter, so how to manufacture HEPA filter to meet consumer demand has become an urgent need of manufacturers. One of the problems solved [1-2]. It is well known that the resistance performance and filtration efficiency of the filter are two important indicators for evaluating the filter. This paper attempts to analyze the filtration performance and resistance performance of the HEPA air filter of different filter materials by experiments [3], and the different structures of the same filter material. The filtration performance and resistance properties of the filter provide a theoretical basis for the filter manufacturer.

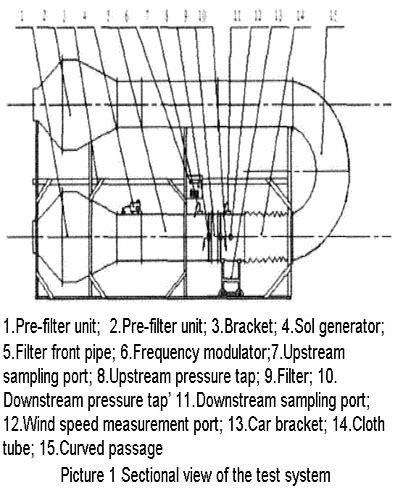

1 Test method analysis

There are many methods for detecting HEPA air filters, and different countries have different standards. In 1956, the US Military Commission developed the USMIL-STD282, a HEPA air filter test standard, and the DOP method for efficiency testing. In 1965, the British standard BS3928 was established, and the sodium flame method for efficiency detection was used. In 1973, the European Ventilation Association developed the Eurovent 4/4 standard, which followed the sodium flame detection method. Later, the American Society for Environmental Testing and Filter Efficiency Science compiled a series of similar standards for recommended testing methods, all using the DOP caliper counting method. In 1999, Europe established the BSEN1822 standard, which uses the most transparent particle size (MPPS) to detect filtration efficiency [4]. The detection standard of China adopts the sodium flame method. The HEPA air filter performance detection system used in this experiment is developed based on the US 52.2 standard. The detection method uses a caliper counting method, and the aerosol uses P.A.O particles.

1. 1 main instrument

This experiment uses two particle counters, which are simple, convenient, fast and intuitive compared to other particle concentration testing equipment [5]. The above advantages of the particle counter make it gradually replace other methods and become the main test method for particle concentration. They can count both the number of particles and the particle size distribution (ie, counting count), which is the core equipment of this experiment. The sampling flow rate is 28.6 LPM, and its carbonless vacuum pump has the characteristics of low noise and stable performance. If the option is installed, the temperature and humidity as well as the wind speed can be measured and the filter can be tested.

The detection system uses aerosols using P.A.O particles as dust to be filtered. We use the aerosol generators (Aerosol generations) of the TDA-5B model produced in the United States. The range of occurrence is 500 – 65000 cfm (1 cfm = 28.6 LPM), and the concentration is 100 μg / L, 6500 cfm; 10 μg / L, 65000 cfm.

1. 2 clean room

In order to improve the accuracy of the experiment, the 10,000-level laboratory was designed and decorated according to the US Federal Standard 209C. The coating floor is used, which is characterized by the advantages of terrazzo, wear resistance, good sealing, flexibility and complicated construction. The material is epoxy lacquer and the wall is made of assembled clean room siding. The room is equipped with 220v, 2×40w purification 6 lamps and arranged according to the requirements of illumination and field equipment. The clean room has 4 top air outlets and 4 air return ports. The air shower room is designed for single ordinary touch control. The air shower time is 0-100s, and the wind speed of any adjustable circulating air volume nozzle is greater than or equal to 20ms. Because the clean room area is <50m2 and the staff is <5 people, a safe exit is provided for the clean room. The HEPA filter selected is GB01×4, the air volume is 1000m3/h, and the filtration efficiency is greater than or equal to 0.5μm and 99.995%.

1. 3 experimental samples

The models of the glass fiber filter are: 610 (L) × 610 (H) × 150 (W) mm, baffle type, 75 wrinkles, size 610 (L) × 610 (H) × 90 (W) Mm, with 200 pleats, PTFE filter size 480 (L) × 480 (H) × 70 (W) mm, without baffle type, with 100 wrinkles.

2 Basic principles

The basic principle of the test bench is that the fan is blown into the air. Since the HEPA/UEPA is also equipped with a HEPA air filter, it can be considered that the air has become clean air before reaching the tested HEPA/UEPA. The device emits PAO particles into the pipeline to form a desired concentration of dust-containing gas and uses a laser particle counter to determine the particle concentration. The dust-containing gas then flows through the tested HEPA/UEPA, and the dust particle concentration in the air filtered by HEPA/UEPA is also measured using a laser particle counter, and the dust concentration of the air before and after the filter is compared, thereby determining the HEPA/UEPA. Filter performance. Moreover, sampling holes are respectively arranged before and after the filter, and the resistance of each wind speed is tested by using a tilt micro pressure gauge here.

3 filter resistance performance comparison

The resistance characteristic of HEPA is one of the important characteristics of HEPA. Under the premise of meeting the efficiency of people’s demand, the resistance characteristics are related to the cost of use, the resistance is small, the energy consumption is small, and the cost is saved. Therefore, the resistance performance of the filter has become a concern. One of the important indicators.

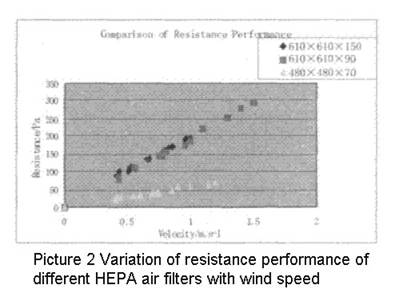

According to the experimental measurement data, the relationship between the average wind speed of the two different structural filters of the glass fiber and the PTFE filter and the filter pressure difference is obtained. The relationship is shown in Figure 2:

It can be seen from the experimental data that as the wind speed increases, the resistance of the filter increases linearly from low to high, and the two straight lines of the two filters of glass fiber substantially coincide. It is easy to see that when the filtration wind speed is 1 m/s, the resistance of the glass fiber filter is about four times that of the PTFE filter.

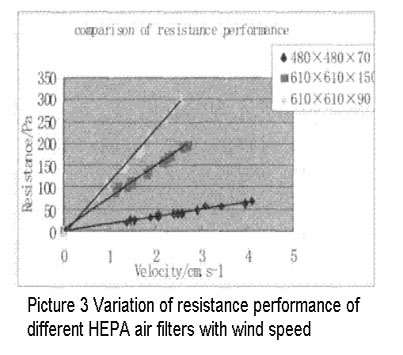

Knowing the area of the filter, the relationship between the face speed and the filter pressure difference can be derived:

It can be seen from the experimental data that as the wind speed increases, the resistance of the filter increases linearly from low to high, and the two straight lines of the two filters of glass fiber substantially coincide. It is easy to see that when the filtration wind speed is 1 m/s, the resistance of the glass fiber filter is about four times that of the PTFE filte

Knowing the area of the filter, the relationship between the face speed and the filter pressure difference can be derived:

Due to the difference between the surface speed of the two kinds of filter filters and the filter pressure difference of the two filter papers, the resistance of the filter with the specification of 610×610×90mm at the same surface speed is higher than the specification 610×. Resistance of the 610 x 150mm filter.

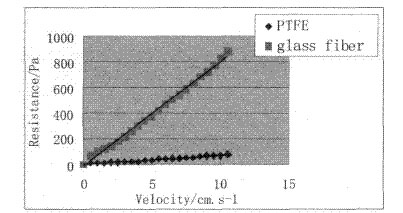

However, it is clear that at the same surface speed, the resistance of the glass fiber filter is higher than the resistance of the PTFE. It shows that PTFE is superior to glass fiber filter in terms of resistance performance. In order to further understand the characteristics of glass fiber filter and PTFE resistance, further experiments were carried out. Directly study the resistance of the two filter papers as the filter wind speed changes, the experimental results are shown below:

This further confirms the previous conclusion that the resistance of glass fiber filter paper is higher than that of PTFE under the same wind speed [6].

4 filter filter performance comparison

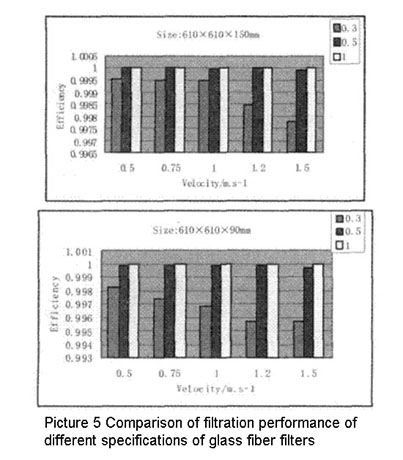

According to the experimental conditions, the filtration efficiency of the filter for particles with a particle size of 0.3 μm, 0.5 μm, and 1.0 μm at different wind speeds can be measured, and the following chart is obtained:

Obviously, the filtration efficiency of the two glass fiber filters for 1.0 μm particles at different wind speeds is 100%, and the filtration efficiency of 0.3 μm and 0.5 μm particles decreases with the increase of wind speed. It can be seen that the filtration efficiency of the filter to the large particles is higher than that of the small particles, and the filtration performance of the 610×610×150 mm filter is superior to the filter of the specification 610×610×90 mm.

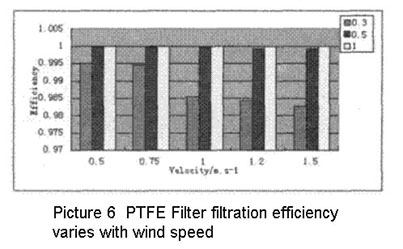

Using the same method, a graph showing the relationship between the filtration efficiency of the 480×480×70 mm PTFE filter as a function of wind speed is obtained:

Comparing Fig. 5 and Fig. 6, the filtration effect of the 0.3 μm, 0.5 μm particle glass filter is better, especially for the 0.3 μm dust contrast effect. The filtration effect of the three particles on 1 μm particles was 100%.

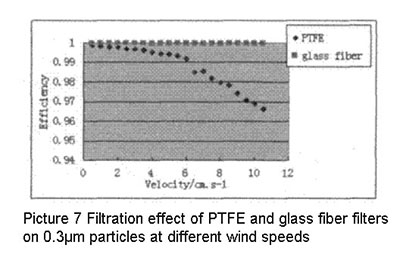

In order to more intuitively compare the filtration performance of the glass fiber filter and the PTFE filter material, the filter performance tests were directly performed on the two filter papers, and the following chart was obtained:

The above chart is obtained by measuring the filtration effect of PTFE and glass fiber filter paper on 0.3 μm particles at different wind speeds [7-8]. It is obvious that the filtration efficiency of PTFE filter paper is lower than that of glass fiber filter paper.

Considering the resistance properties and filtration properties of the filter material, it is easy to see that the PTFE filter material is more suitable for making coarse or sub-HEPA filters, and the glass fiber filter material is more suitable for making HEPA or ultra-HEPA filters.

5 Conclusion

The prospects for different filter applications are explored by comparing the resistance properties and filtration properties of PTFE filters with glass fiber filters. From the experiment we can draw the conclusion that wind speed is a very important factor affecting the filtration effect of HEPA air filter. The higher the wind speed, the lower the filtration efficiency, the more obvious the effect on PTFE filter, and overall The PTFE filter has a lower filtration effect than the fiberglass filter, but its resistance is lower than that of the glass fiber filter. Therefore, the PTFE filter material is more suitable for making a coarse or sub-high efficiency filter, and the glass fiber filter material is more suitable for the production. Efficient or ultra-efficient filter. The glass fiber HEPA filter with a specification of 610×610×150mm is lower than the 610×610×90mm glass fiber HEPA filter, and the filtration performance is better than the 610×610×90mm glass fiber HEPA filter. At present, the price of pure PTFE filter material is higher than that of glass fiber. However, compared with glass fiber, PTFE has better temperature resistance, corrosion resistance and hydrolysis than glass fiber. Therefore, various factors should be considered when producing filter. Combine technical performance and economic performance.

References:

[1]Liu Laihong, Wang Shihong. Development and Application of Air Filters [J]•Filtering and Separation, 2000, 10(4): 8-10.

[2] C. N. Davis Air Filter [M], translated by Huang Riguang. Beijing: Atomic Energy Press, 1979.

[3] GB/T6165-1985 high efficiency air filter performance test method transmittance and resistance [M]. National Bureau of Standards, 1985.

[4]Xing Songnian. Detection method and practical application of high efficiency air filter[J]•Bioprotective Epidemic Prevention Equipment, 2005, 26(1): 29-31.

[5]Hochrainer. Furtherdevelopments of the particle counter

sizerPCS-2000glass fiber [J]•Filter Journal ofAerosolScience, 2000,31(1): 771-772.

[6]E. Weingartner, P. Haller, H. Burtscher etc. Pressure

DropAcrossFiberFilters[J]•Aerosol Science, 1996, 27(1): 639-640.

[7]Michael J.M and Clyde Orr. Filtration-Principles and Practices[M].

New York:MarcelDekkerInc, 1987•

[8] Zhang Guoquan. Aerosol mechanics – theoretical basis of dust removal and purification [M] • Beijing: China Environmental Science Press, 1987.

Post time: Jan-06-2019