Storage, installation and technical specifications

Product characteristics and uses

Ordinary HEPA filter (hereinafter referred to as filter) is a purification equipment, which has a filtration efficiency of 99.99% or more for particles with a particle size of 0.12μm in air, and is mainly used for high-purity such as electronics, medicine, food, precision instruments and cosmetics. Degree of industry. It must be transported, stored and installed in strict accordance with this requirement to ensure that the filter can be used normally.

Transportation and storage

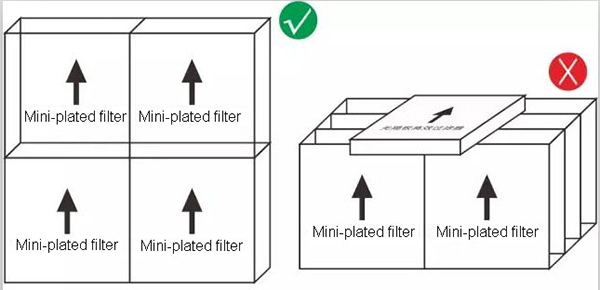

1. During transportation, the filter should be placed in the direction of the box to prevent the filter material, partitions, etc. from falling off and being damaged by vibration. (See Figure 1)

2. During transportation, it must be transported in the diagonal direction of the box. The transport personnel should be careful to prevent the filter from slipping during transportation and damage the filter. (See Figure 2)

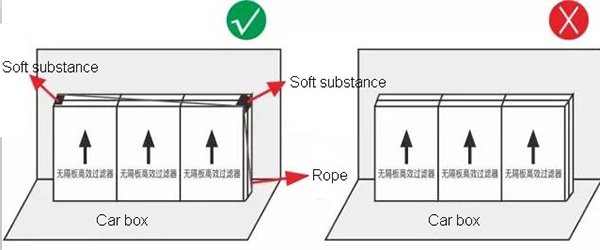

3. When loading, the stacking height is up to three layers. Use a rope to tie it up when transporting. When the rope crosses the corner of the box, a soft object is used to separate the rope from the box. Protect the cabinet. (See Figure 3)

4. The filter should be placed on a dry surface in the direction of the box identification. No external force of more than 20 kg can be applied to the filter.

5. The storage location should be an environment with small changes in temperature and humidity, clean, dry and good ventilation system.

6. When storing and placing the filter in the warehouse, use the mat board to separate the filter from the ground to prevent the filter from getting wet. (See Figure 4)

7. The stacking height should not exceed three layers to avoid damage when the filter is over-stressed and deformed and transported again.

8. If the storage period is more than three years, it should be retested.

Unpacking

1. Remove the tape from the outside of the box in a flat place, open the cover, take out the pad, turn the case so that the filter is placed on the ground, and then pull the carton up. (See Figure 5)

2. After unpacking, during the handling process, both hands and other objects must not collide with the material. If the filter material is accidentally touched, it should be scanned again even if it is visually invisible.

Installation and adjustment

1. The filter should be installed in a normal temperature, normal pressure, and normal humidity environment. If you need to install in a special environment (such as high humidity, high temperature), please use our special high efficiency filtration products. If the working conditions are bad, the filter life will be shortened and it will not work properly even after installation. Before installation, the appearance of the filter should be tested for deformation, damage, and damage to the filter material. If any of the above conditions are found, contact the company in time.

2. The sealing between the filter and the mounting frame (or the box) must be paid attention to during the installation process. It is better to press the bolt to press one third of the thickness of the gasket. In order to ensure the sealing performance of the filter and the installation box, it is recommended to use the gasket provided by the company. (Be sure to use our high temperature resistant gasket when using a high temperature filter).

3. When replacing the filter, be sure to wipe the inner wall of the static pressure box or the air supply tube thoroughly to prevent the rust and dust particles on the box from falling on the filter, causing damage to the filter material.

4. When installing, be sure to pay attention to the airflow direction of the filter. You can install it according to the wind direction indicator “↑” of the filter label. The direction of the arrow is the filter outlet.

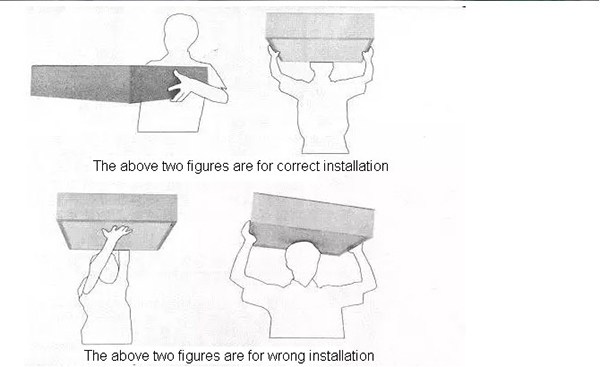

5. When installing, hold the surrounding frame with your hand and slowly move it into the air supply port. Do not use the special hand and head to hold the filter material to avoid the filter material breaking and affect the filtration efficiency. (See Figure 8)

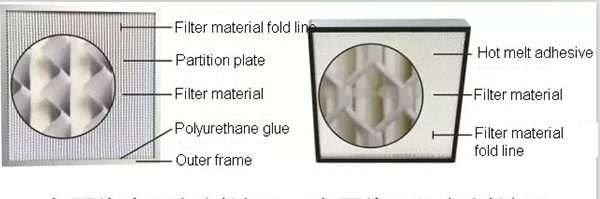

The filter structure

The left picture shows the separator filter, and the right picture shows the separatorless filter.

Service life and maintenance

1. Under normal circumstances, when the medium resistance of the filter is twice the initial resistance, it should be replaced.

2. The cleanliness should be checked regularly on the clean area. The data to be tested should meet the design requirements of the clean plant. If the requirements are not met, the filter should be scanned and the leak tightness of the system checked. If the filter leaks, it should be glued or replaced. When the system is used again after long-term deactivation, the clean room should be scanned.

3. In order to extend the service life of the filter, the primary and secondary filter should be replaced frequently.

Problems and solutions

| Phenomenon | Reason | Solution |

| A small amount of particles when scanning | 1. There are particles on the surface of the filter material.2. Frame leakage | 1. Allow the system to supply air for a period of time, using airflow to clean the filter.2. Repair adhesive |

| Side leakage after installation | 1. Sealing strip is damaged2. Installation frame or tuyere leakage | 1. Replace the sealing strip2. Check the frame or tuyere and seal it with sealing glue |

| Unsatisfactory inspection of clean system after installation | Indoor relative return air is not enough pressure for negative pressure or air supply system | Increase system air supply |

| Found a lot of leakage | Filter damage | Replace the filter |

| The air supply system has reached the rated air supply rate but the surface wind speed of the filter is too small. | The filter has reached the rated dust holding capacity | Replace the filter |

Commitment

According to the principle of product quality first and customer first, the company will satisfy the customer’s requirements as soon as possible. In the event of a failure, the problem is solved first, and then the purpose of the responsibility is analyzed.

Reminder: Please read the storage and installation instructions of the high-efficiency air filter carefully so that you can understand and use the high-efficiency filter properly. Otherwise, the company will not be responsible for the damage caused by human error.

Illustration (the picture on the left is the correct operation, the picture on the right is the wrong operation)

Figure 1 The filter should not be laid flat during transport and storage, and placed according to the sign on the box.

Figure 2 Carrying on the diagonal of the filter, no gloves.

Figure 3 The rope is fastened in transport and the corners are protected by soft objects.

Figure 4 The application of the mat plate during storage separates the filter from the ground to prevent moisture.

Figure 5 When the filter is taken out, the box should be turned over. After the filter is placed on the ground, the box is pulled up.

Figure 6 The filter should not be placed on the ground at random. It should be placed in the direction “↑”of the box.

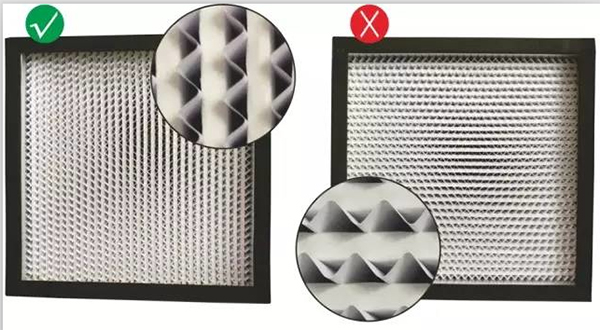

Figure 7 When installing the filter side air supply, the filter wrinkles should be perpendicular to the horizontal direction.

Figure 8 When installing, hold the surrounding frame with your hand and slowly move it into the air supply port. Do not hold the filter material with your hands and head to avoid tearing the filter material and affect the filtration efficiency.

Post time: Feb-03-2014